News

Space Delivery Project “RETURN to EARTH” Third Round Launch Scheduled for Early November!!

In addition to research & development materials and promotional use, also launching new space use projects aiming to promote food and D&I

Items planned to be exposed on the Exposed Facility platform on the International Space Station for approx. 6 months, and then returned to Earth around autumn 2024

PDF Here

Selection of payload items

Tokyo—Space BD, a leading Japanese space startup, would like to announce the third round of the Space Delivery Project “RETURN to EARTH,” a space use project. Payload items from research centers, educational institutions, and private sector companies located in Japan and abroad have been decided on, and these items are planned to be launched to the International Space Station (ISS) on the SpaceX Falcon 9 rocket in early November 2023. In addition to items for research & development use as well as promotional use that were among the payload items in the first and second rounds, in this third round there are new food and D&I promotion projects. The winning idea from a business contest is also planned to be launched into outer space. The payload items in this third round are planned to be loaded into the Exposed Facility platform device on the ISS and spend approx. 6 months exposed to space, after which they will be returned to Earth in summer 2024 on a resupply mission and returned to their origin around autumn 2024.

■Upcoming schedule

10th November 2023 Loaded on to SpaceX Falcon 9 rocket & launched

November 2023 – Around summer 2024 Payload items exposed to space for approx. 6 months on the ISS Exposed Facility platform, and then returned to Earth on a resupply mission

Around autumn 2024 Payload items returned to origin

Space BD is calling any customer who is interested in research & development, company branding, or marketing activities that make use of space. If you are interested please contact us at pr@space-bd.com.

■ Space Delivery Project “RETURN to EARTH”

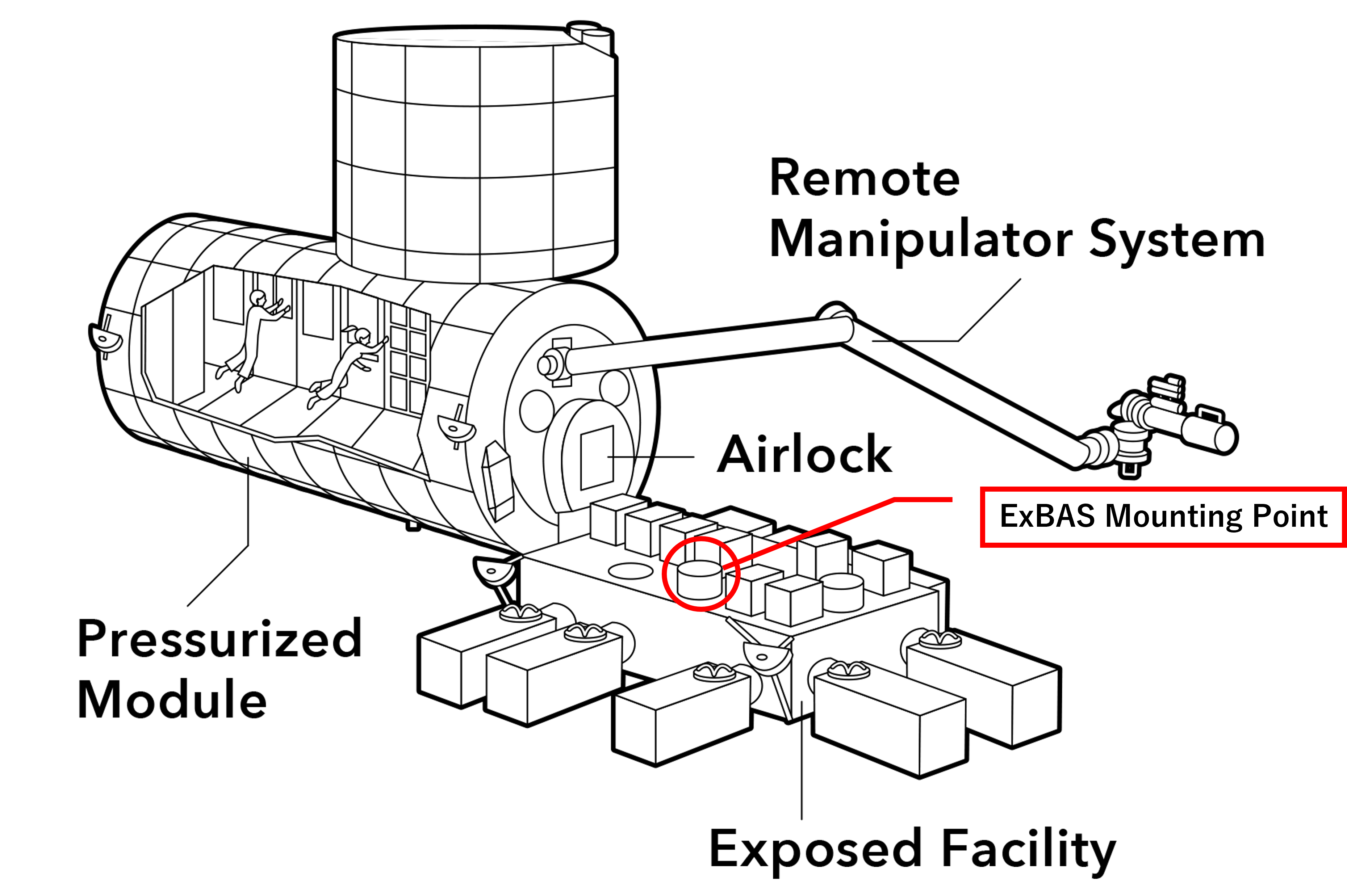

This project makes use of the small simple exposure experiment device (ExBAS*) installed in the medium exposure experiment adapter (i-SEEP) of the ISS Kibo. Space BD called for participation among a wide range of organizations and is providing a variety of support, including payload item selection, launch, and the return to Earth.

▼Space Delivery Project “RETURN to EARTH” introductory video

▼News release about the Space Delivery Project “RETURN to EARTH” Round Two

▼News release about the Space Delivery Project “RETURN to EARTH” Round One

*About ExBAS

As a user of i-SEEP, Space BD has jointly developed ExBAS in collaboration with JAXA since 2020. The use of ExBAS enables Space BD to provide future services for exposure of materials, etc. to space. In addition to the conventional uses of space for research purposes, Space BD hopes to broaden the horizons for the use of space by encouraging a wider range of more general use.

■Comment from Hoshiko Nakata, Business Development / Engineer, Space BD

I was so excited to hear the news that the payload items in this third round of the Space Delivery Project “RETURN to EARTH” are ready for launch. We have expanded the use of space with the payload items in this third round beyond what was achieved in the first and second rounds. This achievement was made possible with the great creativity and effort of the teams at JAXA and NASA, as well as from our collaboration partner companies. Thank you all very much. We have a variety of plans underway for once the payload items are back on Earth to deliver new possibilities for the use of space to all of you, and we hope you will keep an eye out for more news on these initiatives.

■Space Delivery Project “RETURN to EARTH” Third Round Participating Companies and Organizations

| Oita Prefecture

“Space Letterpress Printing Project” (Toshihiro Katayama, Takeshi Kimoto, Yuji Tokuda, Mayuki Nishijima) |

<microcosmos>

~The Future of Space and Earth~ |

|

| Comment from Takeshi Kimoto, Member of the Space Letterpress Printing Project

This project began with the Oita Prefecture “Space Business Talent Training Seminar,” and now the project is sending a piece of letterpress printing, one of the three great inventions of the world, into space. The relationship of space and Earth was carved as a symbol into this item, with the keyword “harmonious cycle.” After the return to Earth the project intends to create a work of art using this piece of printing and make our shared vision a reality. |

||

| Department of Space Systems Engineering, School of Engineering, Kyushu Institute of Technology | <Promotion>

Aluminum plate printed with the Kyushu Institute of Technology logo and the wishes of the students |

|

| Comment from Minoru Iwata, Associate Professor, Department of Space Systems Engineering, School of Engineering, Kyushu Institute of Technology

I would like to express our gratitude for everyone’s support and cooperation that enabled us to have this opportunity. The Iwata Laboratory (Extreme Environment Materials Laboratory) is conducting research activities to energize the space industry through research, development, and demonstrations focusing on the environmental degradation of materials used in space. In my view, many people still do not know that materials degrade in the harsh environment of space. I hope that seeing the plate returned from space will make the students of the Kyushu Institute of Technology and other people in the community feel more of an affinity to space development, and that they will become interested in space development and material degradation in the space environment. We will continue to push forward in our research activities so that we can keep on developing initiatives to energize the space industry through the development and demonstration of new technologies. |

||

| -Human beings everybody noodles- to space!!! | <Food / promotion>

Ramen ingredients for -Human beings everybody noodles- (noodles, soup, green onions, bamboo shoots, roasted pork, and ramen bowls) and logo plates |

|

| Comment from Takahiro Matsumura, Representative Director, UNCHI Co., Ltd.

Ever since I was 10 years old my dream was to open a ramen shop, and at 24 I opened -Human beings everybody noodles-. 10 years have passed since then, and through this project I hope to convey to everyone around the world the excitement of actually sending -Human beings everybody noodles- ramen into space. The mission of UNCHI is to “change the world with the power of ramen.” Through this project, we will take the lead in bringing more energy to Osaka and the world! Thank you for your support. |

||

| Thermo Fisher Scientific Japan Group | <Promotion>

Aluminum plate printed with the Thermo Fisher logo |

|

| Comment from Hiroo Murota, Representative, Thermo Fisher Japan Group

Thermo Fisher’s mission is to “To enable our customers to make the world healthier, cleaner and safer,” and we contribute to the further development of science and technology. Thank you for this valuable opportunity. |

||

| EXPLOR Biologics Pty Ltd | <Promotion>

Aluminum plate printed with the EXPLOR Biologics Pty Ltd logo |

|

| Comment from Joshua Chou, CEO, EXPLOR Biologics Pty Ltd

EXPLOR Biologics is a space biology and medicine company that focuses on advancing human healthcare through space technologies. We are excited to work closely with Space BD in advancing this exciting field of space discovery. |

||

| Artificial Satellite Group, Research & Development Center, SEIREN CO., LTD. | <Research use / promotion>

Comparative study of conventional and new carbon fiber composite materials with laser-processed product names |

|

| Comment from Yoshinaga Shimada, Chief, Artificial Satellite Group, Research & Development Center, SEIREN CO., LTD.

SEIREN’s policy is “Exploring Unknown Possibilities!” We are pleased to be participating in the space exposure test of a new carbon fiber composite material, and we will strive to deliver higher value-added products to our customers by leveraging the knowledge gained from the experience. We would also like to thank Space BD and all the stakeholders involved for providing us with this wonderful testing opportunity. |

||

| Tampopo 6 Team | <Research use>

Examination of bio‑organic synthesis and microbial viability in the space environment to elucidate the origin, movement, and survival of life in space |

|

| Comment from Shin-ichi Yokobori, Associate Professor, Tokyo University of Pharmacy and Life Sciences

For this sixth round of the Tampopo research team, in addition to the space exposure experiments on microorganisms, moss plants, and organic matter that have been performed so far, we will newly perform space exposure experiments on yeast and extracellular substances produced by microorganisms. As a result, we hope to accumulate new knowledge on the origin of life and space survival. |

||

| HelioX Cosmos Co., Ltd. | <Promotion>

Aluminum plate printed with HelioX Cosmos logo |

|

| Comment from Bill Chang, CEO, HelioX Cosmos

We are grateful to our faithful partner Space BD for its continuous support. Along with thoroughly carrying out our mission to “Democratizing Space Utilization” and introducing space business to the public for exploring new collaborations, we have decided to proactively become the first Taiwanese company to launch logo to space embodied with pioneer spirits from our CEO and core members. The logo symbolizes an exciting space era and will be presented as we promoting business in the future. |

||

| D&I Promotion Project, LIXIL Corporation | <D&I Promotion>

Company’s commercial products: aluminum alloys, steel plates, sanitary ware, ECOCARAT (porous ceramics), exterior wall tiles (porcelain tiles) |

|

| Comment from Kazuyoshi Kitamura, Project Leader, D&I Promotion Project, LIXIL Corporation

We joined this project as a D&I promotion initiative. We are leveraging the wisdom and skills of our diverse employees to select launch materials, conduct preliminary evaluations using our own test facilities, and process materials and cases. As a result, we are able to foster exchange between our employees, and develop and discover new human talent. The common theme of “space” has become an opportunity to increase LIXIL’s overall strength. |

||

■Space Delivery Project “RETURN to EARTH” Third Round Collaborators

| Company name | Collaboration details | Comment |

|---|---|---|

| Adachi Textile Co., Ltd. | Contracted for vacuum packing at a level as close to outer space as possible to protect payload items that are not space environment resistant | Yuki Miotani, Director

As we did previously, we have been given this opportunity to take on a new challenge. Adachi Textile is grateful to everyone involved in this initiative. On this occasion we developed and are employing a new packaging technology for ramen and artworks. We are still in the middle of the journey, but we hope that you will support us in the success of this project and the return to Earth! |

| APC AEROSPECIALTY INC. | Contracted for manufacture of packaging materials to protect payload items that are not space environment resistant | Ichirou Yamashita, Representative Director and President

We are very pleased to be participating once again in the ExBAS3 project. We sincerely hope that this round of payload items will also be safely transported to space and successfully returned to Earth. As a company that specializes in aerospace, we offer quality and reliability, and are proud of our collaboration. We wish for the continued success of the project. |

| Ohori Grinding Company | Contracted for grinding and finishing several types of difficult-to-machine metal materials intended for use as exposure test specimens to the same dimensions and same conditions | Ken Ohori, Representative Director

We are honored to be involved in this project, and leveraging our specialty grinding capabilities. Both myself and our employees are delighted that our technology is going to space and being of help in the experiments. We look forward to seeing the results of the experiments upon the return to Earth. |

| Metal Technology Co., Ltd. | Contracted for grinding and finishing several types of difficult-to-machine metal materials intended for use as exposure test specimens to the same dimensions and same conditions | Haruyoshi Yamazaki, Factory Deputy Head, Toki Factory

Metal Technology is a company that contributes to society through metals under the slogan “the metal solution.” We are honored to be able to help connect to the future. We wish for the success of this project. |

| Core Machinery, Inc. | Contracted to produce a variety of commemorative aluminum plates, using the company’s specialized surface processing technology to express complex designs on aluminum sheets | Masaki Okamoto, Representative Director

Every time we are engaged in the manufacture of aluminum plates, we feel the potential of our own processing technology. Once again, we overcame various difficulties and were able to give shape to ideas. I wonder what kind of texture the vivid color of the anodized aluminum will have after its stay in the harshness of space? We look forward to its safe return. |

| Sagami Coating Co., Ltd. | Contracted for the atomic oxygen resistant coating necessary to maintain the design of commemorative aluminum plates after exposure to space | Toshiyuki Sagami, Representative Director and President

This was our first attempt to coat a traditional Japanese textile called Nishijin brocade. In the coating process, we made every effort to maintain the shape of the fabric so that it would not fray. We considered the characteristics of the ink while coating the design plate. Thank you again for this valuable opportunity. We hope that the sample items to be launched will travel through space and return to Earth, and that they will be a source of hope for the next stage of the project. |

| Toagosei Co., Ltd. | Providing an atomic oxygen resistant coating agent developed jointly with JAXA, which is needed to protect the commemorative aluminum plates | Naomasa Furuta, Senior Manager, New Product Development Division

We are honored to continue to participate in such a dream project. On this occasion, we are thrilled that our coatings have been applied to materials that have no previous experience on Earth. We hope that our materials will perform as expected and that this project will continue to grow. |

| YUKI Precision Co., Ltd. | Contracted to manufacture the frame plates for fixing each payload item to the side part of ExBAS | Tohru Hirano, Business Development Department

We are deeply honored to be able to help send products into space again in this round. |

■About Space BD

We at Space BD are a one-stop provider of solutions for those in the space utilization field. Not only can we deliver payloads to space by a variety of methods and facilitate the use of International Space Station assets, but we can also assist with everything from business plans to hands-on technical operations. As of June 2023, Space BD’s performance record marked over 70 satellite projects and over 400 orders.

U R L:https://space-bd.com/en/